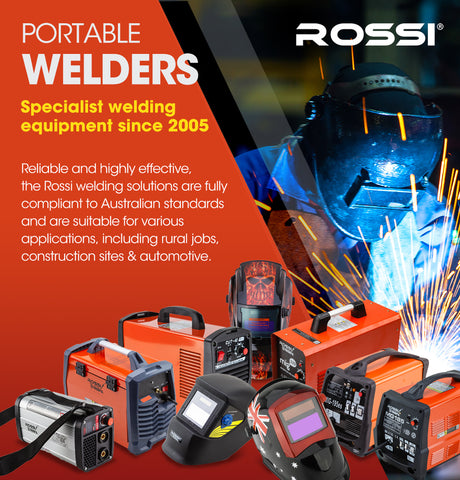

Welding guns and plasma cutters provide reliable cutting and joining solutions, offering durable construction, precise performance, and compatibility with various metals. Ideal for fabrication, repair, and industrial tasks. Find the right tool today.

- 9% off

During Days

Vevor Mig Welder Welding Machine MIG-270 MIG MMA TIG IGBT DC Inverter Welder Digital Display

$421.99 AUD$464.39Unit price /UnavailableLow stock (13 units) DDV219

$441.99 AUDUnit price /UnavailableVery low stock (3 units)DDV219

ROSSI NextGenTIG/MMA 200A Welder TIG-200, Ar Gas, HF Start, Regulator Included

$293.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

$698.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

$514.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 40 Amp Plasma Cutter, Portable Oxy Torch Welder Cutting Machine, 15A Plug

$391.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 300 Amp MIG Stick Welder, Portable DC Gas Gasless Inverter Welding Machine, 15A Plug

$563.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 250 Amp Stick Welder, Portable Arc MMA Inverter Welding Machine, 15A Plug

$170.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 200A MIG/MAG/MMA/ARC/TIG Multi-Purpose Welder MIG-200, Flux/Solid Wire/CO2 Or Argon Gas

$367.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 200 Amp Portable Inverter Arc Stick Welder, MMA DC Gas Inverter Welding Machine, 15A Plug

$133.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

Rossi 18pc Welding Consumables Kit to Suit MIG/MAG 14-15AK Torch, Includes Tips, Shield Cups

$30.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 170Amp MIG ARC Stick Welder, with Carry Case & Accessories, 15A Plug

$256.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

$207.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 160 Amp Inverter Arc MMA Stick DC Welder, Portable Welding Machine, 15A Plug

$146.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

$637.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

ROSSI 140A MIG/MAG/MMA/ARC/TIG Multi-Purpose Welder MIG-140, Flux/Solid Wire/CO2 Or Argon Gas

$280.99 AUDUnit price /UnavailableLow stock (10 units)DDV219

$195.99 AUDUnit price /UnavailableLow stock (10 units)During Days

$29.99 AUDUnit price /UnavailableLow stock (10 units)During Days

$29.99 AUDUnit price /UnavailableLow stock (10 units)- 38% off

DDV274

Gasless MIG Welding Wire E71T-11 Flux Cored 0.8mm

$42.99 AUD$69.00Unit price /UnavailableVery low stock (3 units)

Why Choose Duringdays

When it comes to investing in the right tools for your workshop, choosing the right supplier is just as important as choosing the right equipment. At Duringdays, we are dedicated to providing both professionals and hobbyists with reliable Welding Guns & Plasma Cutters that deliver performance, safety, and durability. Every product is carefully selected to ensure that you get consistent results, whether you're undertaking small projects or large-scale welding tasks.

Trusted Quality and Performance

Our customers rely on us for the best Welding Guns & Plasma Cutters because we maintain strict quality standards. Every tool is sourced from trusted manufacturers and built to withstand demanding environments. We understand that welding and cutting tools are a long-term investment, which is why we provide equipment designed to last, offering consistent performance you can depend on time and again.

Customer Support You Can Count On

Outstanding customer service is at the heart of what we do. From the moment you browse through our range until well after your purchase, our team is here to assist you. Whether you need product recommendations, troubleshooting advice, or after-sales support, Duringdays makes sure you never feel left on your own.

Easy Returns with Peace of Mind

We know that sometimes a product may not be the right fit. That is why we offer a hassle-free return process for approved items. Conditions apply, and you can find full details on our policies by visiting our Shipping & Returns page. We also provide a 14-day money-back guarantee to give you additional confidence when making a purchase, with conditions outlined on our website.

Warranty Protection

On top of flexible returns, our range is backed by a manufacturer warranty to ensure your investment is protected. Knowing your purchase is supported provides peace of mind and allows you to focus on the job at hand. Detailed warranty conditions are available through our Warranty Policy page.

Why This Matters

Selecting the right supplier means access to durability, ongoing support, and straightforward solutions when you need them most. At Duringdays, we bring you the Top Welding Guns & Plasma Cutters while ensuring your purchasing journey is simple, fair, and backed by trusted policies. This combination of high-quality products, excellent service, and guaranteed protection makes us a partner you can rely on for the long term.

How to Choose the Welding Guns & Plasma Cutters

Selecting the right tools for welding and cutting is essential to ensure both efficiency and safety in your workshop or job site. At Duringdays, we understand that choosing from a wide array of Welding Guns & Plasma Cutters Australia can feel overwhelming, which is why we have created this guide to help you make the most confident decision. Below, we explore the most important factors to consider before investing in these essential tools.

1. Size and Power Requirements

When purchasing welding guns or plasma cutters, size and power capacity are crucial. Smaller, lightweight options are ideal for minor repair tasks or hobby projects, while larger, industrial-sized equipment is suited for heavy-duty, continuous-use applications. Assess the thickness of the materials you frequently work with and select a gun or cutter with adequate amperage output and duty cycle. The key is finding a balance between maneuverability and performance, ensuring the equipment matches your specific workload.

2. Material Compatibility

The type of material you are working with greatly influences the equipment choice. Different welding guns and plasma cutters are designed to handle specific metals such as mild steel, stainless steel, or aluminum. Some advanced models include settings and consumables that allow seamless transitions between multiple metals, adding versatility to your workspace. For professionals who work with various types of metals, this flexibility can save both time and effort.

3. Durability and Build Quality

Durability directly impacts the lifespan and reliability of your tools. Products designed with robust construction and quality materials withstand frequent use and reduce long-term maintenance. Duringdays carefully selects every tool with user reliability in mind, so you can trust that your purchase is built to endure. Look for ergonomic handles, reinforced cables, and hardened housings, as these features ensure the equipment can withstand the rigors of both industrial and on-site environments.

4. Features and Functionality

Modern welding guns and plasma cutters now come equipped with advanced features tailored for greater efficiency and ease of use. Adjustable air pressure, safety locks, pilot arc starts, and digital displays are just a few options available. If you are new to these tools, we recommend selecting a unit with intuitive controls for quick mastery. Experienced professionals may prefer more feature-rich models that allow greater customization and control over cutting speeds, heat levels, and arc stability.

5. Style and Ease of Use

The design and style of these tools should not be overlooked. Ergonomics matter, particularly for long sessions, as they reduce fatigue and increase productivity. Comfortable grips, lightweight bodies, and user-friendly connections make for smoother operations. Beyond performance, choosing a style that complements your workflow enhances your overall efficiency, especially if your work demands frequent tool swaps or movement across job sites.

Confidence in Every Purchase

At Duringdays, we believe that confidence in a purchase is just as important as the purchase itself. That is why all our welding guns and plasma cutters come backed not only by manufacturer warranties but also a 14-day money-back guarantee for your peace of mind, with conditions applying. For full details about coverage and conditions, please visit our Warranty Policy page.

Why Shop at Duringdays?

Choosing the right welding gun or plasma cutter is a decision that should support your current projects and prepare you for future needs. With Duringdays, you gain access to a curated range of trusted products designed to deliver lasting value. Our expert selections provide a balance between reliability and quality, ensuring that whether you are a hobbyist or a seasoned professional, you will find options that align with your goals and budget. For many customers, the journey begins with searching for Affordable Welding Guns & Plasma Cutters, but what truly matters is finding tools that consistently perform under pressure. At Duringdays, that commitment is at the heart of every product we offer.

Final Thoughts

Selecting the right welding gun or plasma cutter requires careful thought about the job at hand, the materials you regularly use, and the features that would make your workflow smoother. By paying attention to factors like size, material compatibility, durability, functionality, and style, you position yourself for success. Combined with the peace of mind offered through our warranties and return policy, shopping with Duringdays ensures you make an informed, confident choice that aligns perfectly with your craft and projects.

Benefits of Choosing Welding Guns & Plasma Cutters

At Duringdays, we understand that investing in the right welding and cutting equipment is crucial for both professionals and enthusiasts. That’s why we provide a wide selection of Welding Guns & Plasma Cutters that combine reliability, performance, and value. Whether you are tackling industrial projects or smaller tasks, our range is designed to give you the confidence and efficiency you need.

Durability Built to Last

Welding and cutting work requires tools that can withstand intense usage. Duringdays offers Welding Guns & Plasma Cutters that feature rugged construction and high-quality materials, ensuring durability under demanding conditions. These products are made to endure heat, pressure, and repeated use, helping you avoid frequent replacements and enjoy long-term value.

Design Versatility

Our selection is engineered with versatility in mind, making them adaptable for a wide range of applications. From precision cutting to heavy-duty welding, you can find equipment that performs across various projects. Versatility also means greater convenience, as a single tool can often handle multiple tasks efficiently.

Cost-Effectiveness Without Compromise

At Duringdays, we focus on delivering a balance between affordability and quality. Customers can access Affordable Welding Guns & Plasma Cutters that don’t sacrifice performance for price. With the right investment, you get equipment that saves costs over time through efficiency and reduced maintenance needs.

Ease of Maintenance

Every tool eventually requires upkeep, but our Welding Guns & Plasma Cutters are designed for easy maintenance. Whether it’s replacing consumables or conducting routine servicing, the straightforward design reduces downtime. This ensures you can focus on completing your projects rather than troubleshooting your equipment.

Eco-Friendliness

Modern operations call for more environmentally conscious choices. Duringdays provides Welding Guns & Plasma Cutters with designs that emphasize energy efficiency and reduced waste. By cutting cleaner and welding more efficiently, you help minimize excess material use while lowering overall energy consumption.

Perfect for Australian Conditions

Australia’s unique environment demands tools that can perform under tough and variable conditions. Duringdays offers options like Cheap Welding Guns & Plasma Cutters and premium models that are engineered to thrive in both workshop and outdoor settings. This makes our selection among the best Welding Guns & Plasma Cutters available for Australian users.

Peace of Mind with Every Purchase

When you shop at Duringdays, you benefit from a 14-day money-back guarantee and manufacturer warranty, with conditions applying. For complete details on coverage and terms, visit our Warranty Policy page. This assurance ensures every customer can make a purchase with confidence.

By choosing Welding Guns & Plasma Cutters from Duringdays, you are investing in strength, versatility, and reliability backed by dedicated customer support. Whether you are an industry professional or a hobbyist, our products provide the performance you need to get the job done right.